-

SEMICONDUCTOR

FAILURE

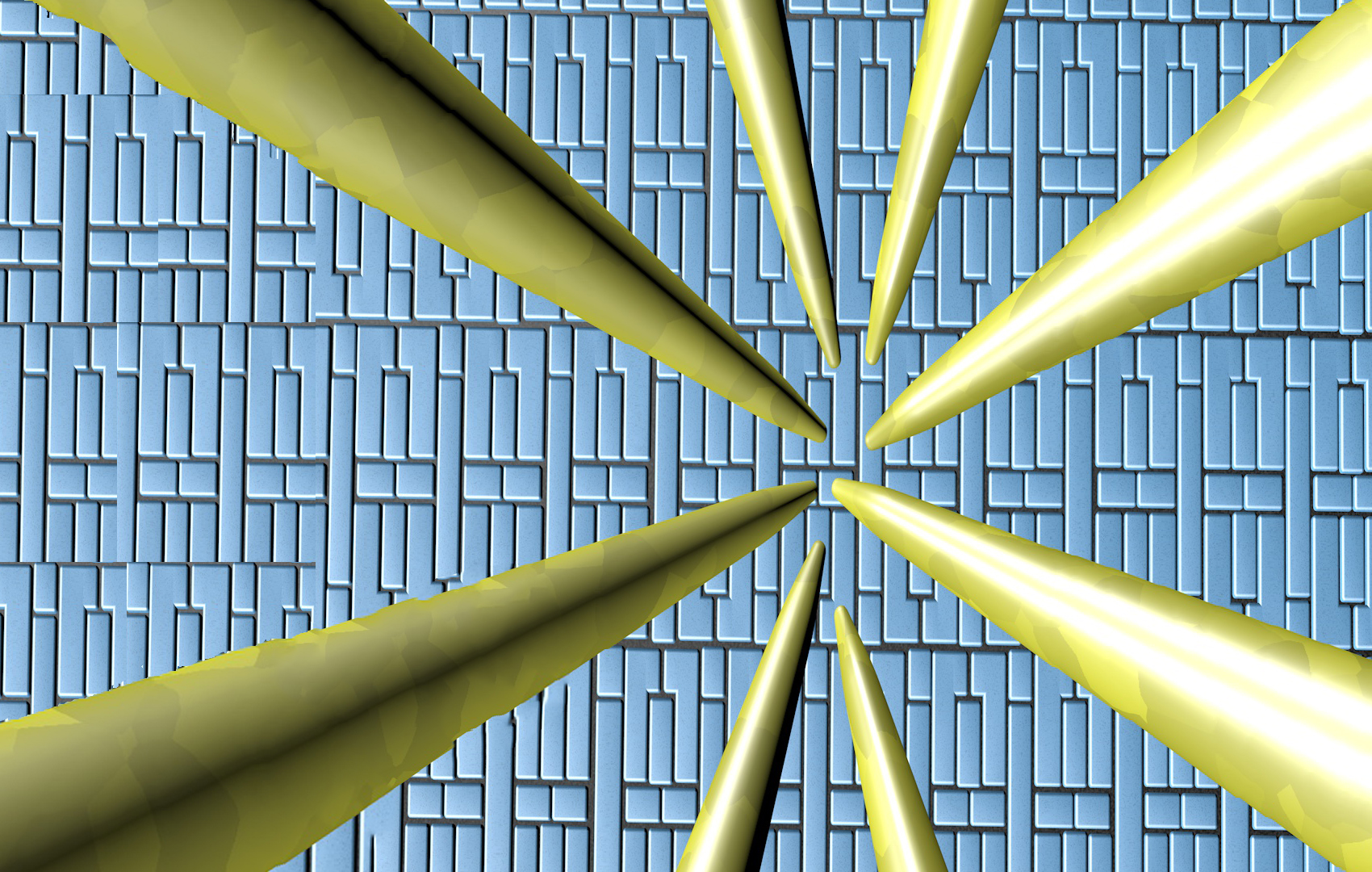

ANALYSISDuring the development and fabrication of semiconductors, engineers diagnose malfunctioning devices in a process called failure analysis (FA). Tiptek’s probes and needles are used in two FA analytical methods: Nanoprobing and FIB/SEM lamella sample preparation.

For nanoprobing, Tiptek probes touch the tiniest features on semiconductor chips and allows their electrical connectivity and characteristics to be tested. Additionally, for FIB/SEM lamella sample preparation, Tiptek LTN ™ lamella transfer needles deliver cross-sections of semiconductor chips to holders for subsequent analysis. -

ATOMICALLY

PRECISE

MANUFACTURING

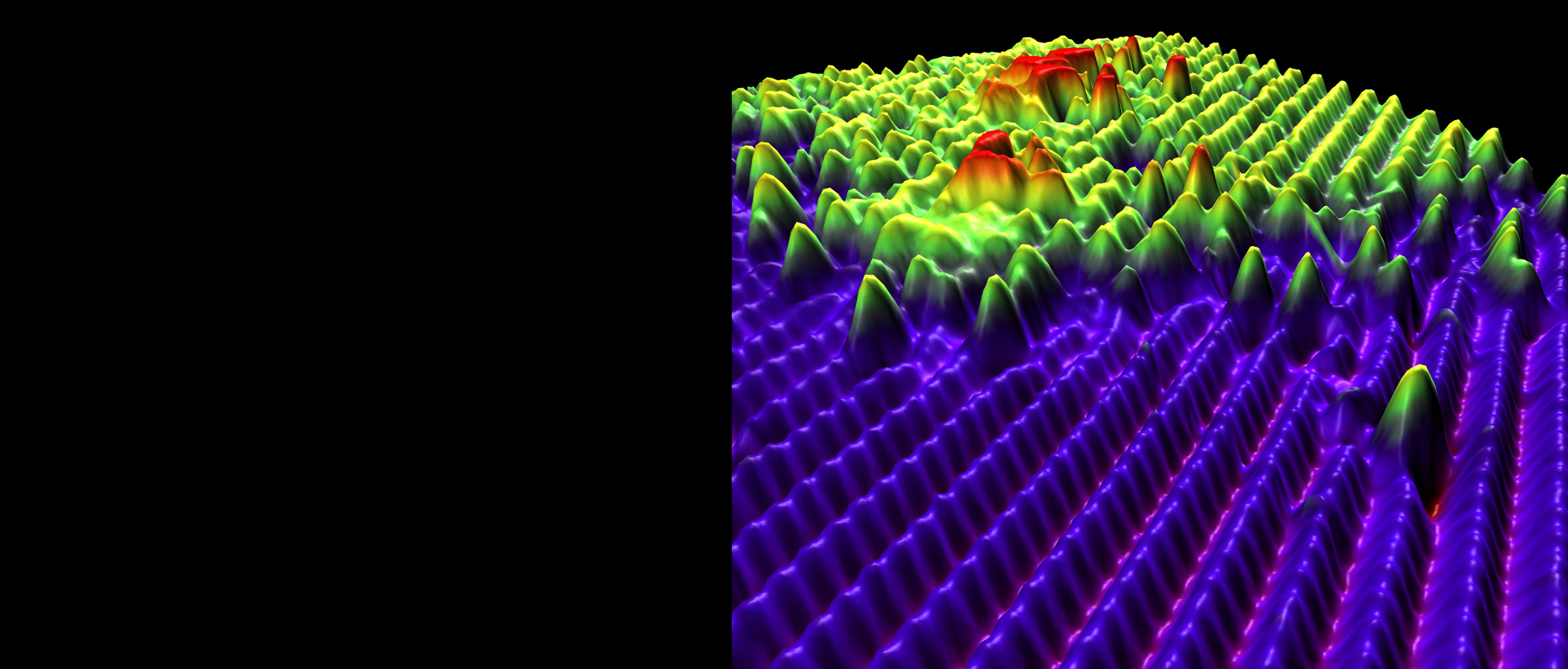

(APM)Atomically Precise Manufacturing (APM) is an emerging manufacturing technology in which materials, structures, devices, and finished goods are fabricated such that every atom is positioned at an exactly specified location relative to the other atoms. In this method, the finished goods have no defects or imperfections. Tiptek is developing a high-yield process to manufacture probes for APM that allow large structures to be assembled.

-

SCANNING

TUNNELING

MICROSCOPY

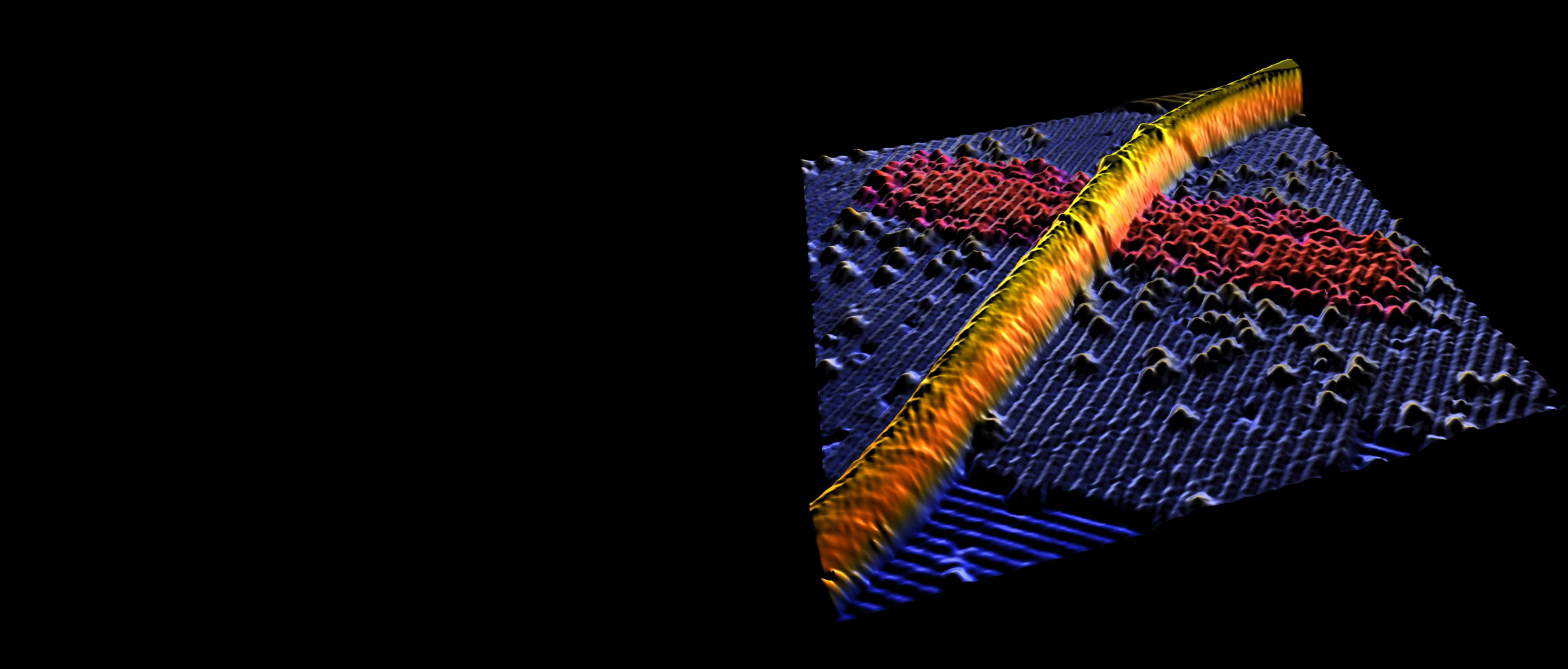

(STM)A Scanning Tunneling Microscope (STM) images a surface with atomic resolution using an electrically biased probe. In this technique, the STM user brings the probe in close proximity to a surface and establishes a tunneling current. While holding current constant, the probe is rastered across the surface and the relief map created from this motion is a direct representation of the atomic structure of the surface. Tiptek STM probes image and analyze surfaces with atomic precision.

Applications

© 2020 by Tiptek, LLC

Comments are closed.